Rotary vane pumps RV22, RV26

Characteristic

- oil-free operation

- source of the vacuum without additions

- compact and reliable construction

- easy installation and maintenance

- low weight and dimensions

- continuous running without vibrations

- economic operation

Applications:

- Printing machines

- Environmental sector

- Food industry

- Pneumatic transport

- Automation

- Packaging industry

- Forest industry

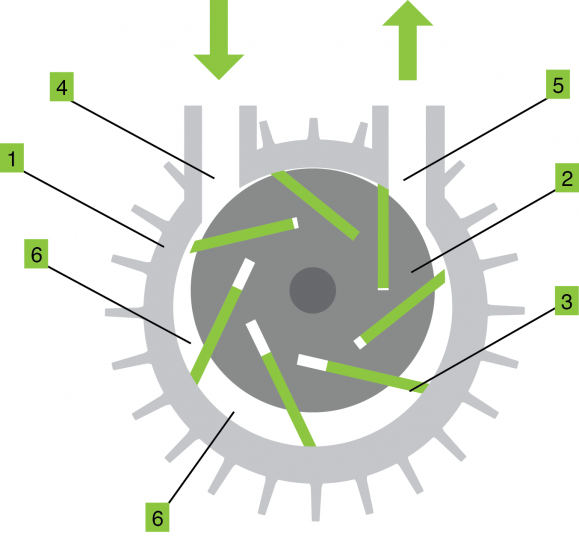

Principle:

The principle of operation of the rotary vane vacuum pump is based on the rotating lamellas. Rotor (2) is situated excentric on the top in the cylindrical stator (1), so rotor is almost touching the stator. The lamellas (4) are pushed towards the wall of the stator by centrifugal force. Between two lamellas and stator it comes to the volume change of the compression chambers (7) by stator rotation, due to this fact the gas is sucked.

1) Stator

2) Rotor

3) Carbon lamellas

4) Input

5) Output

6) Compression chamber

| Model | Discharge capacity (L/min) 50/60Hz |

Vacuum (mbar) |

Motor (IP54), 50 Hz / 60Hz | Thermal protector |

Noisiness (dB) |

Weight (kg) |

blower connection thread) |

||

| Power | Voltage | Current | |||||||

| (kW) | (V) | (A) | |||||||

| Single phase | |||||||||

| RV 22 | 120/135 | 850 | 0,31 / 0,38 | 230 (110) | 1,6 / 1,8 (3,5) | yes | 59/62 | 13 | 3/8” |

| RV 26 |

130/155 | 850 | 0,31 / 0,38 |

230 (110) | 1,9 / 2,2 (3,8) | yes | 59/62 | 14 | 3/8” |

Vacuum pumps Rotary vane RV, Piston pumps VP, Luquid ring pump LRDatasheets (pdf/2MB)

| RV blowers/exhausters meet Directive 2002/95/EC of European Parliament and of the Council of 27 January 2003 on the restriction of the use of certain hazardous substances in electrical and electronic equipment. | RV blowers/exhausters conform to the European Community’s Machinery Directive (CE). |