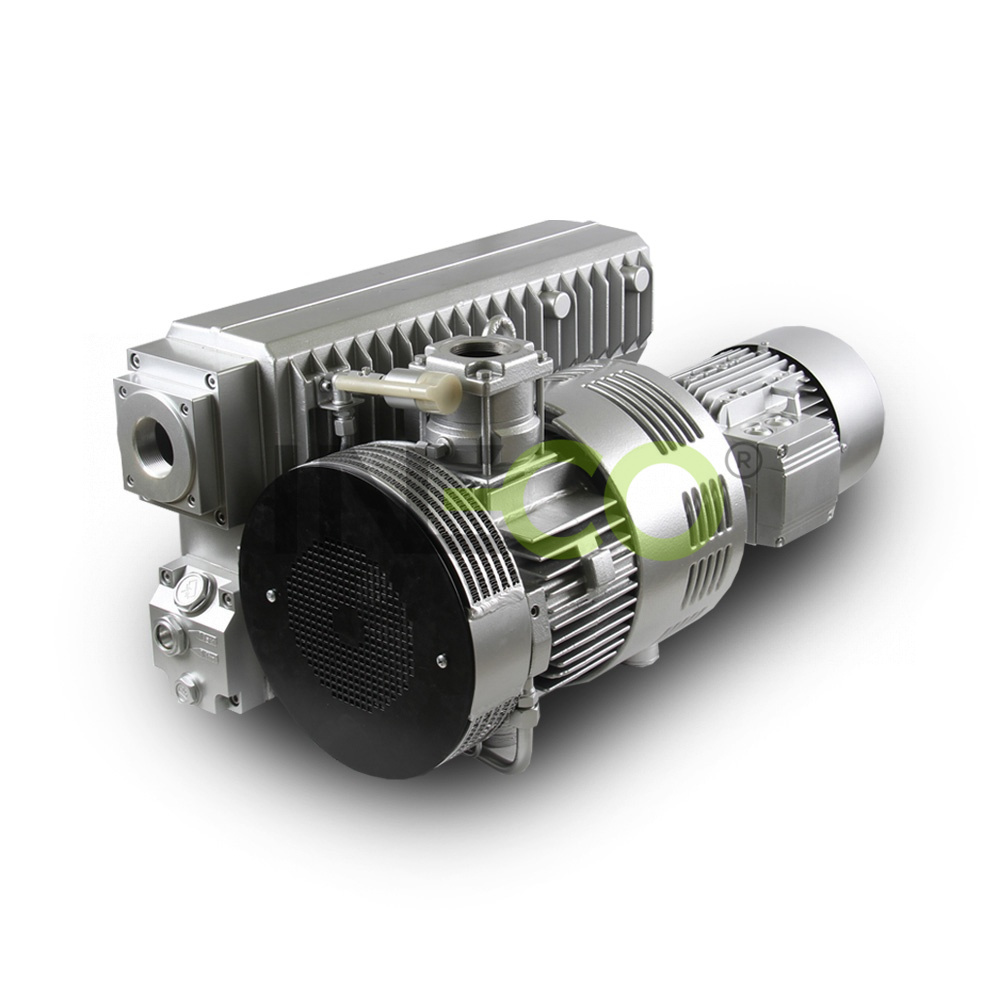

Oil rotary vane vacuum pumps ORV

Characteristic:

> Compact and delivered easy to install

> Low maintenance and wear, thanks to optimal shaft speeds

> Low noise and vibration levels

> Quiet, cool operation

> Environmentally Friendly

> Long vane life

> Minimal maintenance

> Continuous duty rated

Applications:

> Packaging

> Degassing

> Pneumatic Conveying

> Drying Processes

> Holding and Lifting Goods

> Distillation

> Evacuation

> Removal

> Coating

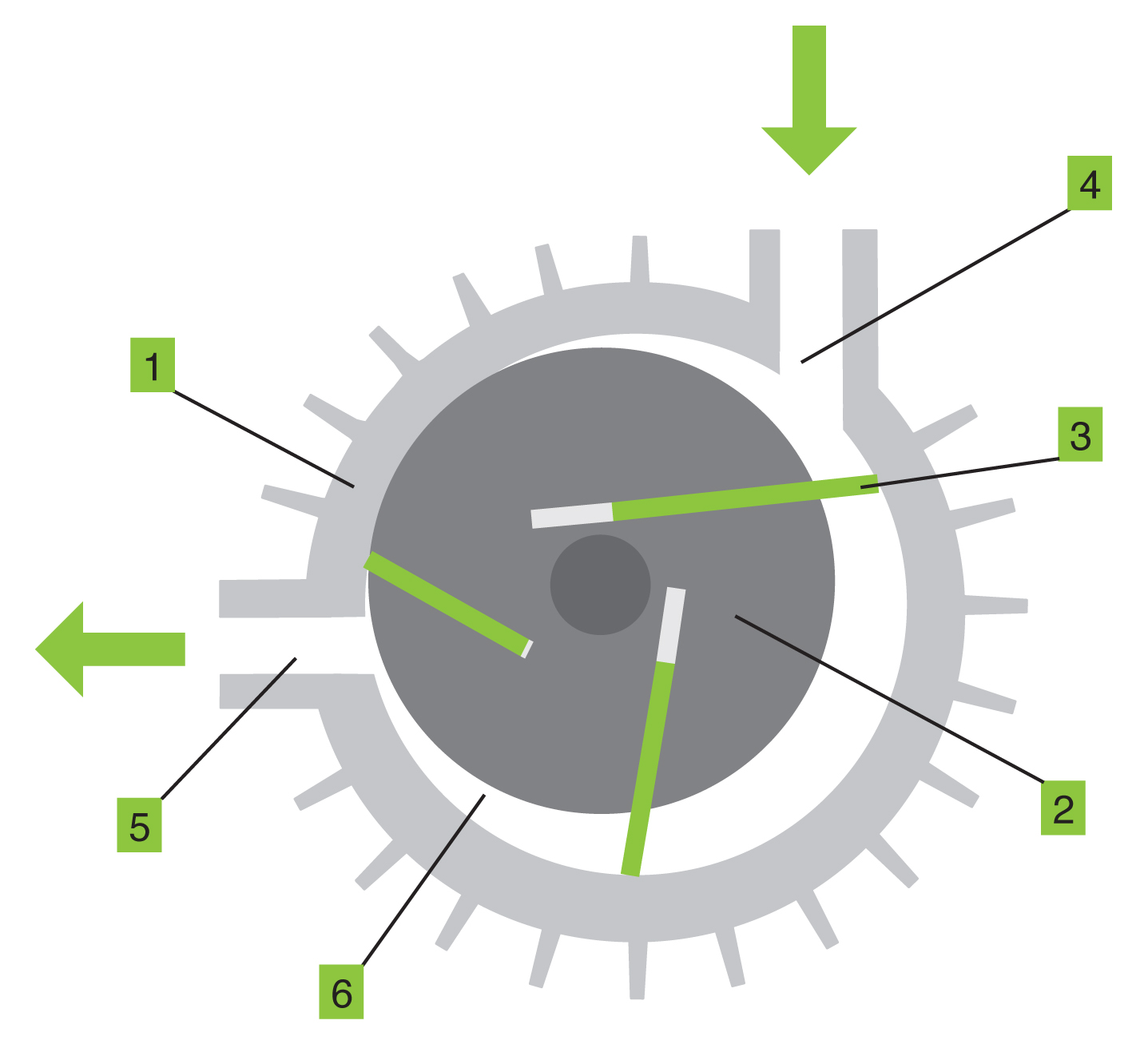

Principle of Oil rotary vane vacuum pumps:

The principle of operation of the Oil rotary vane vacuum pump is based on the rotating lamellas. Rotor (2) is situated excentric on the top in the cylindrical stator (1), so rotor is almost touching the stator. The lamellas (4) are pushed towards the wall of the stator by centrifugal force. Between two lamellas and stator it comes to the volume change of the compression chambers (7) by stator rotation, due to this fact the gas is sucked.

The oil in the pump serves as a lubricant for the internal parts and seals the fins against the stator, helping to achieve a higher vacuum.

1) Stator

2) Rotor

3) Carbon lamellas

4) Input

5) Output

6) Compression chamber

| Type |

Nominal pumping speed (m³/h) |

Ultimate pressure ABS

|

Nominal

motor rating |

Nominal

motor speed (min-¹) |

Noise level (ISO 2151) (dB) |

Oil capacity (l) |

Weight approx.

(kg) |

Dimesions (L x W x H) (mm) |

Blower connec- tion (inner thread) |

| Three phases |

|||||||||

| ORV 08 | 8 | 2 | 0.37 | 2800 | 60 | 0.25 | 11 | 330 x 165 x 152 |

G 3/8” |

| ORV 10 | 10 | 2 | 0.55 | 2800 | 69 | 0.30 | 18 | 340 x 210 x 205 |

G 1/2” |

| ORV 16 | 16 | 2 | 0.55 | 2800 | 69 | 0.30 | 18 | 340 x 210 x 205 |

G 1/2” |

|

ORV 20 |

20 |

2 |

0.75 |

3000 |

66 |

0.45 |

20 |

338 x 232 x 220 |

G 3/4” |

|

ORV 25 |

25 |

2 |

0.75 |

2800 |

64 |

0.5 |

38 |

405 x 253 x 210 |

G 3/4” |

|

ORV 40 |

40 |

0.1 |

1.1 |

1500 |

65 |

1 |

38 |

640 x 285 x 262 |

G 1¼” |

|

ORV 63 |

63 |

0.1 |

1.5 |

1500 |

67 |

2 |

55 |

635 x 406 x 289 |

G 1¼” |

|

ORV 100 |

100 |

0.1 |

2.2 |

1500 |

67 |

2 |

73 |

736 x 406 x 289 |

G 1¼” |

|

ORV 160 |

160 |

0.1 |

4.0 |

1500 |

70 |

5 |

140 |

854 x 492 x 411 |

G 2” |

|

ORV 200 |

200 |

0.1 |

4.0 |

1500 |

72 |

5 |

140 |

854 x 492 x 411 |

G 2” |

|

ORV 250 |

250 |

0.1 |

5.5 |

1500 |

72 |

6.5 |

190 |

1000 x 581 x 410 |

G 2" |

|

ORV 300 |

300 |

0.1 |

7.5 |

1500 | 74 | 6.5 |

190 |

1075 x 565 x 421 |

G 2" |

|

ORV 630 |

630 |

0.1 |

15 | 1000 | 77 | 15.0 | 700 | 1723 x 912 x 726 |

G 3” |

| Single phase | |||||||||

| ORV 08-1 | 8 | 2 | 0.55 | 2800 | 60 | 0.25 | 11 | 330 x 165 x 152 |

G 3/8” |

| ORV 10-1 | 10 | 2 | 0.75 | 2800 | 69 | 0.30 | 18 | 340 x 210 x 205 |

G 1/2” |

| ORV 16-1 | 16 | 2 | 0.75 | 2800 | 69 | 0.30 | 18 | 340 x 210 x 205 |

G 1/2” |

| ORV 20-1 | 20 | 2 | 0.75 | 3000 | 66 | 0.45 | 20 |

338 x 232 x 220 |

G 3/4” |

| ORV 25-1 | 25 | 2 | 0,9 | 2800 | 64 | 0.5 | 25 | 405 x 253 x 210 | G 3/4” |