INW_Double stage ring blowers / vacuum pumps

Characteristic:

- wide application

- oil free operation

- quiet and low vibration

- low weight

- wide range of types and performance

- easy installation and dismantlement

- minimum moving parts

- simple maintenance

Applications:

- aeration of waste water systems or pond aeration, aquaculture

- agitation (aeration) of the solutions by the galvanic technology

- vacuum cleaning systems – industry cleaners, filters cleaning

- baths - underwater massage, bubble bath, bubble pilar

- drying process, air knifes

- pneumatic conveying system: flour, wheat, powders, synthetic fiber, capsule, etc.

- handling by the suction curve, leafing and sucking by the vacuum, thermograsp packing

- textile industry - vacuum cleaning of production waste

- printing technologies – holding the leaves by sucking

- dental technology - suction device

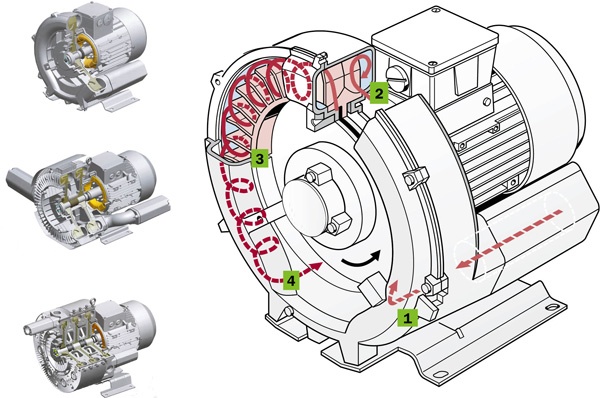

Principle:

Gas is taken into the device via the suction branch with built-in silencer (1). In the side channel (2) the rotor (3) transfers its speed and gas via centrifugal force is pushed toward the compression chamber. This way, along the spiralroute, gas is repeatedly pressed up to the discharge branch (4), from which it is released. With multi-stage blowers, gas flows through multiple compressor chambers placed behind one another, achieving greater pressure differences.

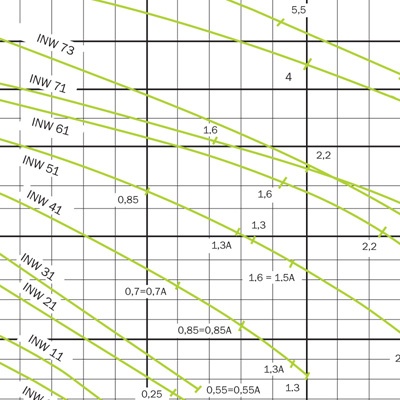

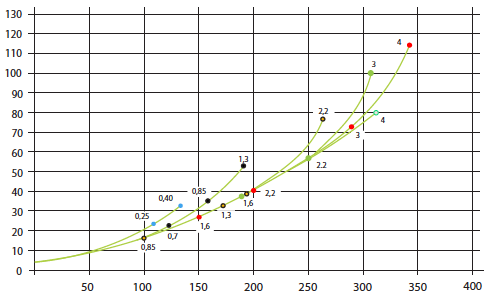

| Type |

Suction (m3/h) |

Pressure / vacuum (mbar) |

Motor (IP55), 50Hz, (60Hz)* |

Noisiness (dB) |

Weight (kg) |

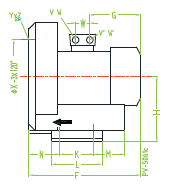

Blower connection (inner thread) |

||

| Power input | Voltage | Current | ||||||

| (kW) | (V) | (A) |

||||||

| Three phases | ||||||||

| INW 220 H26 | 88 | 240/210 | 0,7 | 200-240 ∆ / 345-415 Y | 3,8 ∆ / 2,2 Y | 55 | 15 | G 1¼” |

| INW 320 H26 | 110 | 230/200 | 0,85 | 200-240 ∆ / 345-415 Y | 4,2 ∆ / 2,4 Y | 58 | 17 | G 1¼” |

| INW 320 H36 | 110 | 290/280 | 1,3 | 200-240 ∆ / 345-415 Y | 5,7 ∆ / 3,3 Y | 58 | 20 |

G 1¼” |

| INW 420 H36 | 150 | 280/280 | 1,6 | 200-240 ∆ / 345-415 Y | 7,5 ∆ / 4,3 Y | 66 | 24 | G 1½” |

| INW 420 H46 | 150 | 420/330 | 2,2 | 200-240 ∆ / 345-415 Y | 9,7 ∆ /5,6 Y | 66 | 27 | G 1½” |

| INW 520 H46 | 230 | 410/340 | 3,0 | 200-240 ∆ / 345-415 Y | 12,5 ∆ / 7,2 Y | 72 | 39 | G 2” |

| INW 520 H57 | 230 | 440/390 | 4,0 | 345-415 ∆ | 9,5 ∆ / 5,5 Y | 72 | 43 | G 2” |

| INW 720 H16 | 320 | 190/200 | 2,2 | 200-240 ∆ / 345-415 Y | 9,7 ∆ / 5,6 Y | 73 | 42 | G 2” |

| INW 720 H26 | 320 | 260/280 | 3,0 | 200-240 ∆ / 345-415 Y | 12,5 ∆ / 7,2 Y | 73 | 47 | G 2” |

| INW 720 H37 | 320 | 380/360 | 4,3 | 345-415 ∆ | 10,0 ∆ / 5,8 Y | 73 | 53 | G 2” |

| INW 720 H47 | 320 | 500/440 | 5,5 | 345-415 ∆ | 13,3 ∆ / 7,7 Y | 73 | 66 |

G 2” |

| INW 720 H57 | 320 | 570/440 | 7,5 | 345-415 ∆ | 16,7 ∆ / 9,6 Y | 73 | 71 | G 2” |

| INW 820 H17 | 520 | 260/280 | 5,5 | 345-415 ∆ / 600-720 Y | 13,3 ∆/ 7,7 Y | 74 | 83 | G 2½” |

| INW 820 H27 | 520 | 400/400 | 7,5 | 345-415 ∆ / 600-720 Y | 16,7 ∆/ 9,6 Y | 74 | 85 | G 2½” |

| INW 820 H37 | 520 | 600/430 | 11,0 | 345-415 ∆ / 600-720 Y | 28,0 ∆/ 16,2 Y | 74 | 111 | G 2½” |

| INW 820 H47 | 520 | 670/460 | 15,0 | 345-415 ∆ / 600-720 Y | 32,5 ∆/ 18,8 Y | 74 | 120 | G 2½” |

| INW 920 H17 | 1110 | 270/300 | 12,5 | 345-415 ∆ / 600-720 Y | 28,0 ∆/ 16,2 Y | 74 | 187 | G 4” |

| INW 920 H27 | 1110 | 370/410 | 16,5 | 345-415 ∆ / 600-720 Y | 35,0 ∆/ 20,0 Y | 74 | 189 | G 4” |

| INW 920 H37 | 1110 | 500/440 | 20,0 | 345-415 ∆ / 600-720 Y | 40,0 ∆/ 23,0 Y | 74 | 191 |

G 4” |

| INW 920 H47 | 1110 | 590/440 | 25,0 | 345-415 ∆ / 600-720 Y | 52,0 ∆/ 30,0 Y | 74 | 193 |

G 4” |

| Single phase | ||||||||

| INW 220 A21 | 88 | 240/210 | 0,7 | 200-240 | 4,5 | 55 | 16 | G 1¼” |

| INW 320 A31 | 120 | 280/240 | 1,1 | 200-240 | 7,3 | 58 | 17 | G 1¼” |

| INW 420 A31 | 150 | 290/280 | 1,5 | 200-240 | 9,0 | 66 | 27 | G 1½” |

* 60 Hz please request this information.

INW ring blowersDatasheets (pdf/2MB)

INW HP_high pressure blowers / exhausters can be applied as vacuum pump and compressor in continuous operation over the total stated performance curve range. The motors are available as standard for the input voltage range of 50 and 60 Hz and for protection category IP 54 (protection against dust and splashing water).

Motors are designed according to the DIN EN 60 034/ IEC 34-1 and temperature class F. For the three phase machines the tolerance +/- 10% for fixed voltage and for +/- 5% voltage range. The single phase machines are designed with a +/- 5% tolerance. If only 90% of the maximum allowed pressure will be used for continuous operating then the allowed voltage range add to +/- 10%. The frequency tolerance is maximum +/- 2%.

|

|

Side channel double stage blowers/pumps INW

|

|

|

Side channel double stage blowers/pumps INW |

|

|

|

INW blowers/exhausters meet Directive 2002/95/EC of European Parliament and of the Council of 27 January 2003 on the restriction of the use of certain hazardous substances in electrical and electronic equipment. |

INW blowers/exhausters conform to the European Community’s Machinery Directive (CE). |