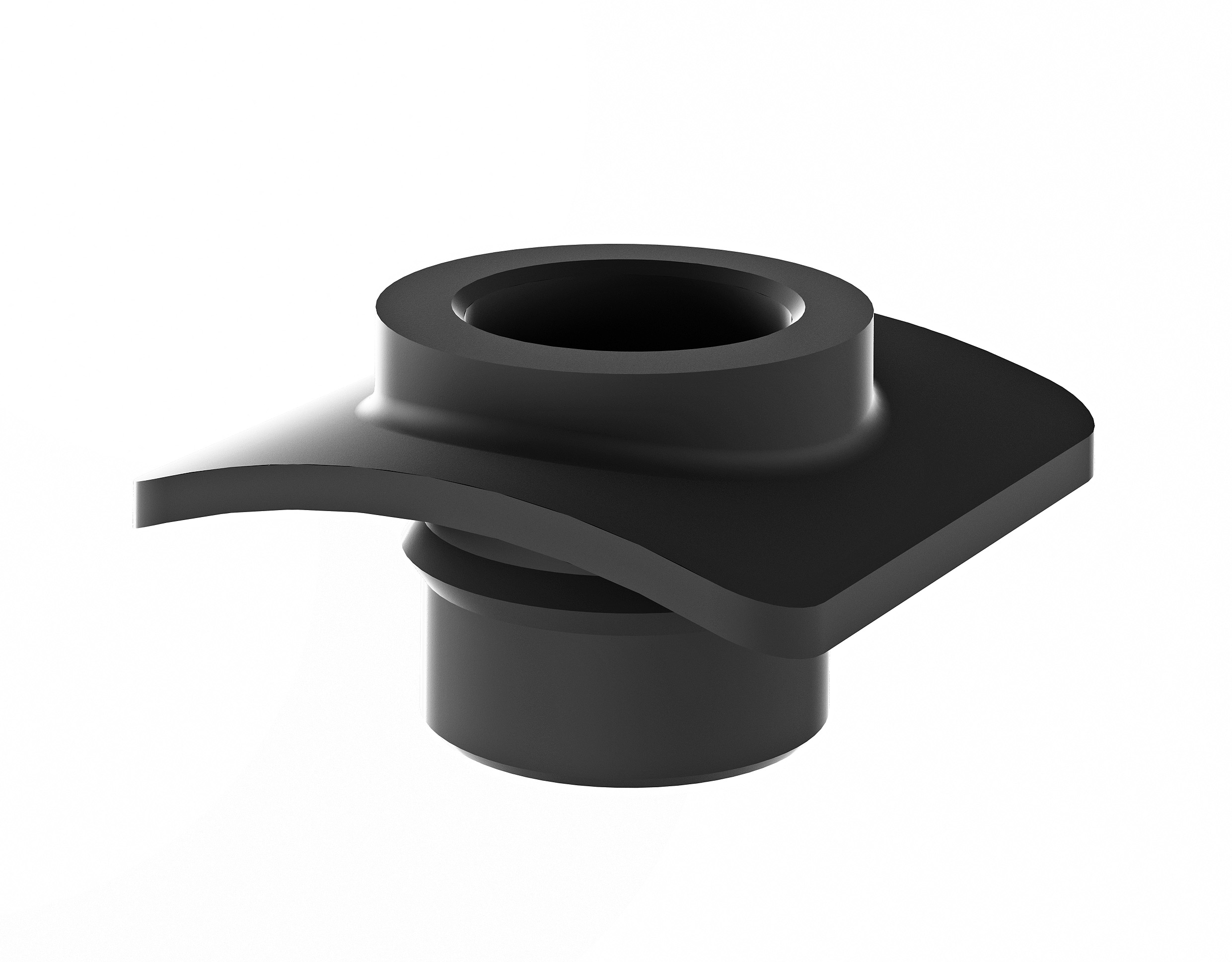

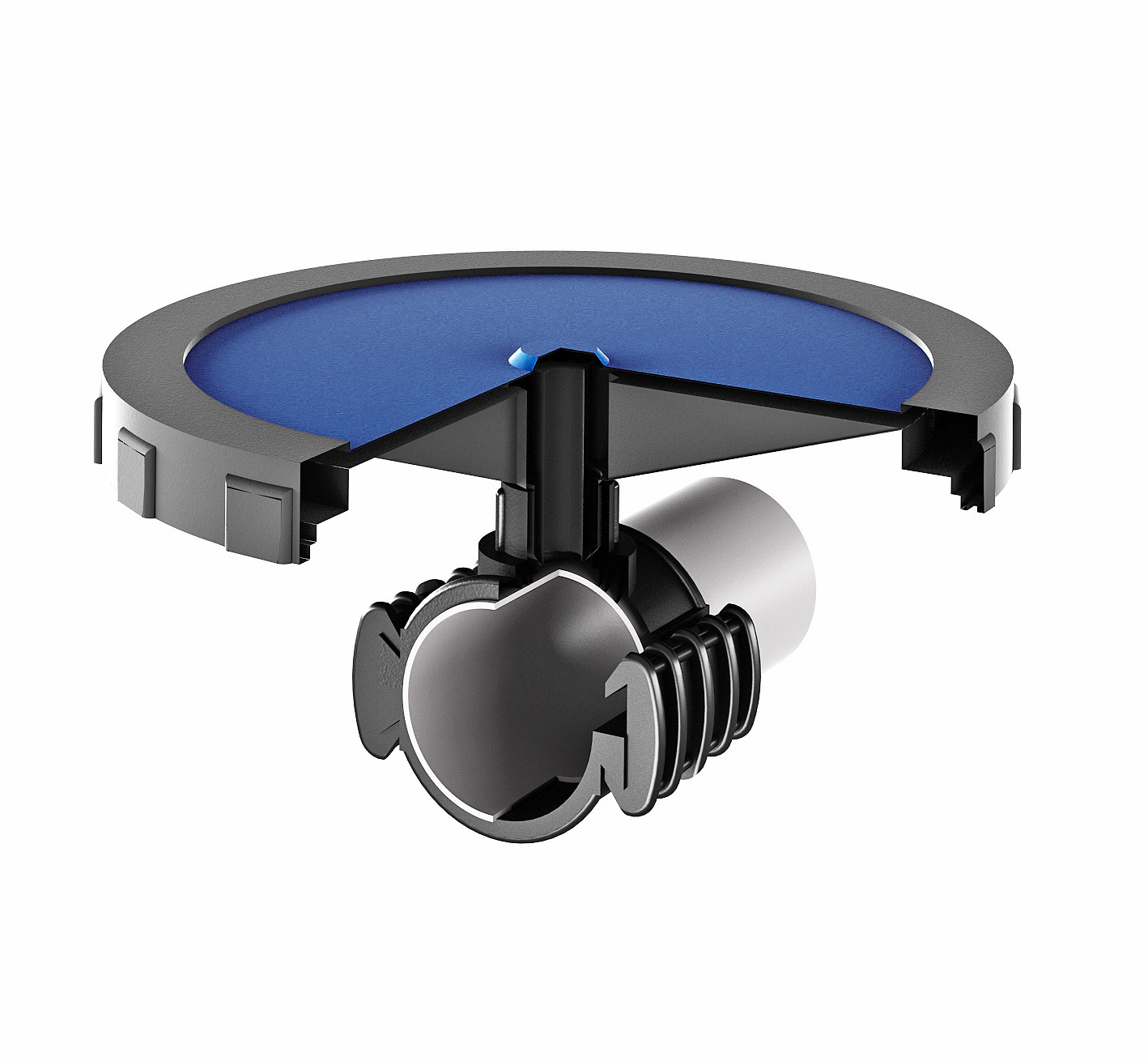

Disc diffusers

Types of disc diffusers |

|

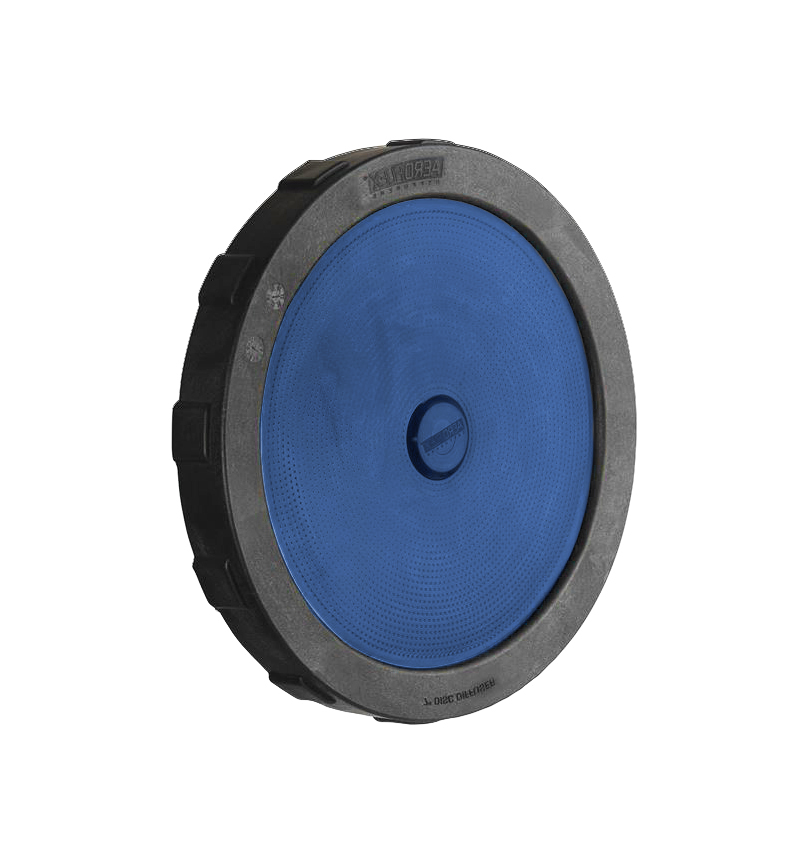

| Disc diffuser with EPDM membrane |

Disc diffuser with silicone membrane |

| - longer lifetime - more resistant to high temperatures |

|

|

|

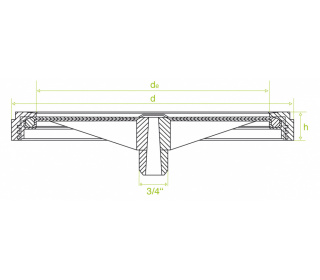

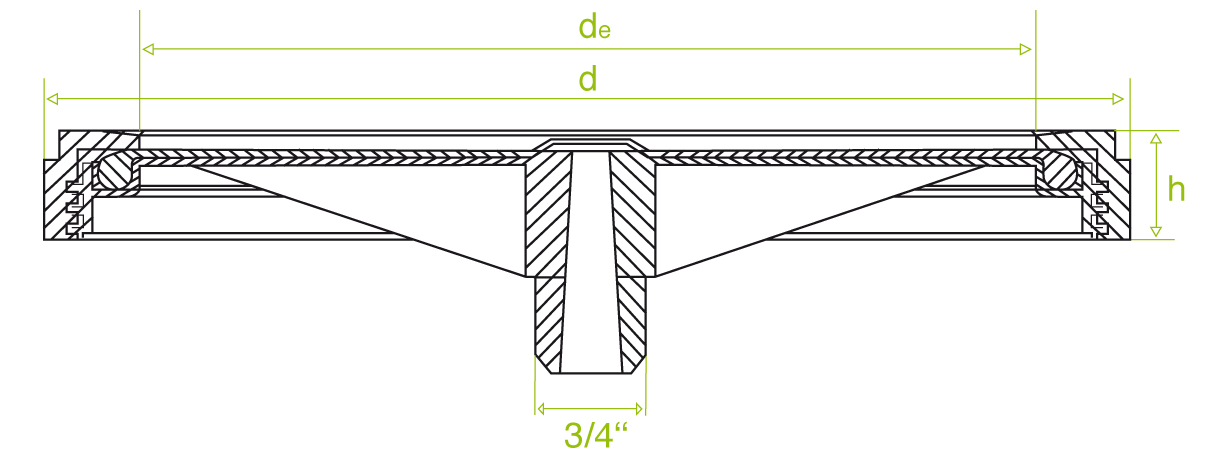

| Size |

Diameter (mm) |

Effective diameter (mm) |

Perforated area (m2) |

Weight (g) |

Maximum flow rate (m3/h) |

Bubble size (mm) |

Operating range (m3/h) |

Connection |

Net height (mm) | Peak output (m3/h) |

| d | de | h | ||||||||

| Disc diffusers | ||||||||||

|

9’’ |

276 | 220 | 0,038 | 670 | 10 | 1-3 | 2-10 | 3/4’’ | 33 | 3-4 |

| 12’’ | 355 | 290 | 0,066 | 1025 | 15 | 1-3 | 2-10 | 3/4’’ | 35 | 3-5 |

Accessories for disc diffusers

| Name of component | Pipe connection gromet | Clamp saddle with slide | Clamp saddle with bolt |

| Diameter d (mm) | - | 63 | 63 |

| 90 |

90 | ||

| Material | rubber | polypropylen (PP) | polypropylen (PP) |

|

|

|

|

|

.jpg) |

|

|

Benefits of disc diffuser:

> High oxygen transfer efficiency

> Low head loss value

> Slit geometry is developed via R&D activities

> Smooth membrane surface prevents the formation of bacterial plaque

> Surface structure enables the bubbles to easily leave the membrane

surface

> Small and intensive slit structure maximised oxygen transfer efficiency

Disc diffuser - applications:

> Wastewater treatments (WWT)

> Renaturation of lakes and rivers